|

125252, Moscow, 12 Aviakonstructor Mikoyan street

Phone: +7 (495) 664-81-71, fax: +7 (495) 664-81-72 |

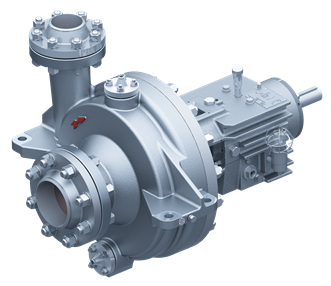

2NK

Centreline-mounted, single-stage overhung pumps

type OH2 (API 610)

DESCRIPTION

2NK series pumps are intended for handling gas condensate, liquefied hydrocarbon gases, crude oil, petroleum products, chemicals and other liquids similar by physical properties (specific gravity, viscosity, density) and corrosion impact on the pumps construction materials. The pumps have been designed in full compliance with API 610 standard of the latest edition as the centerline-mounted, single-stage overhung pumps with radially split casing.

APPLICATION

| Fractionation towers | Pumping systems | Processes |

|

|

|

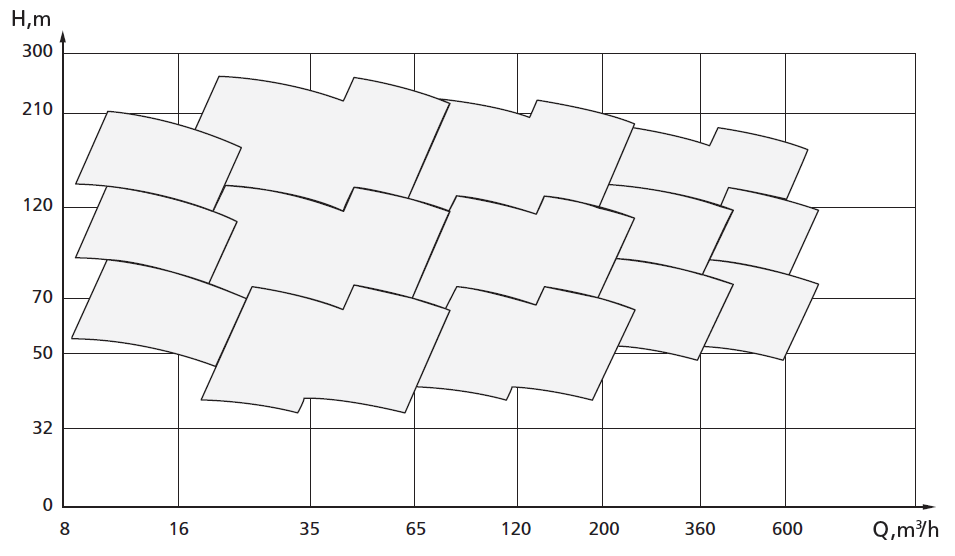

TECHNICAL DATA

- Capacity range: 10 - 720 m3/h

- Head range: 35 – 255 m

- Operation pressure: up to 64 kgf /cm2 (64 bar)

- Pumped media temperature: - 80 … + 400 °C

- Drive power: 11 – 630 KW

- Rotation speed: 3000 rpm

DESIGN FEATURES & ADVANTAGES

- Newly designed flow path provides high efficiency of the pump with rated and optional rotors, retention of the rated performance with slightly trimmed impellers and increased efficiency with deeply trimmed impellers as well as decreased radial load and shaft runout leading to extended operational lifetime of bearings and mechanical seals

- Heavy duty casing design rated for up to 64 bar operation pressure

- Rigid shaft with increased diameters provides minimal deflection and runout that extends operational lifetime of bearings and mechanical seal

- Suction and discharge nozzles design corresponds to ANSI/ASME and DIN/EN

- The pump rotor can be pulled out without dismantling the casing and pipelines to simplify the maintenance operations

- Hard-alloy wearing rings ensure the pump’s performance throughout the whole operational lifetime

- Optional screw-type inducer provided at the suction side for lowered NPSH

- High-efficient cooling system keeps the casing and its bracket at a preset temperature for handling high-temperature liquids. The shaft-mounted fan is optionally available for better bearings cooling

- Bearings lubrication system with improved efficiency provides their long operational lifetime

- Reliable and durable steel membrane coupling reduces vibration and requires no maintenance

SHAFT SEAL

Seal chamber, being complaint with API 610 / ISO 13709 requirements, is designed to fit API 682 / ISO 21049 compliant seals of a cartridge type and provides necessary space for tandem and double mechanical seals installation.

MATERIAL OPTIONS

|

|

S-5

|

S-6

|

S-8

|

C-6

|

A-8

|

D-1

|

D-2

|

Casing |

Carbon steel (WCB) |

12% chromium steel |

316L AUS |

12% chromium steel |

316L AUS |

Duplex steel |

Super duplex steel |

Shaft |

AISI 4140 |

AISI 4140 |

316L AUS |

12% chromium steel |

316 AUS |

Duplex steel |

Super duplex steel |

Bearing housing |

Carbon steel (WCB) |

Carbon steel (WCB) |

Carbon steel (WCB) |

Carbon steel (WCB) |

Carbon steel (WCB) |

Carbon steel (WCB) |

Carbon steel (WCB) |

Impeller |

Carbon steel (WCB) |

12% chromium steel |

316L AUS |

12% chromium steel |

316L AUS |

Duplex steel |

Super duplex steel |

PERFORMANCE RANGE

Back to the section

Incorrect information block