|

125252, Moscow, 12 Aviakonstructor Mikoyan street

Phone: +7 (495) 664-81-71, fax: +7 (495) 664-81-72 |

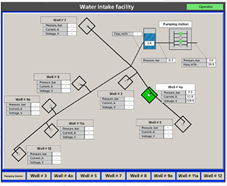

Pumps Supervisory Control And Data Acquisition System (SCADA)

Application:

The pumps supervisory control and data acquisition system (SCADA) is intended for the following tasks

- Data collection about current operation parameters and equipment status at the water supply system objects;

- Remote control of equipment in operation;

- Recording and backing-up of the system events, process and equipment parameters.

- Borehole water intakes;

- Water tanks;

- Pumping stations of the second and third lift;

- Measuring points;

- Pressure boosting stations.

Advantages:

- Reduction of power consumption;

- Reduction of equipment operation costs;

- Reduction of required service personnel number;

- Reduction of response time for emergency situations;

- Increase of efficiency of the water supply objects;

- Increase of intervals between maintenance;

- Real-time access to actual data of the equipment condition with automatic record of system events and back-up;

- Analysis of accumulated data for optimization of equipment operation.

The system operates in the following modes

- Automatic: all the control panels operate with equipment by preset algorithm; the supervisor performs general control and intervenes in the system’s operation, if necessary, in case of abnormal situations, accidents, etc.

- Manual: the supervisor operates with equipment remotely from his automated workstation.

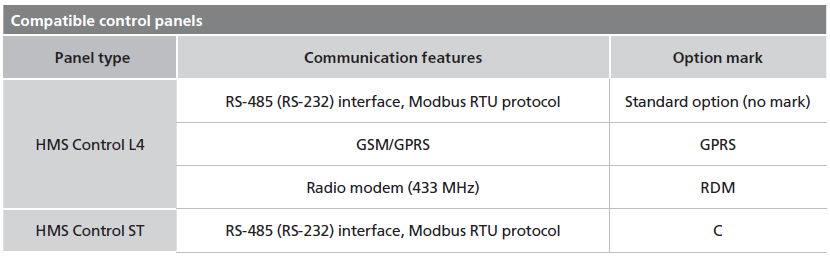

Depending on the objects location and distance between them the following communication ways are applied:

- Wired public or local networks

- GSM / GPRS modem

- 433 MHz radio band

The main elements displayed at the system interface:

- Water supply system objects diagram (can be imposed on the objects’ location map)

- Process scheme of each object

- System events and log of accidents

- Diagrams or tables of the equipment parameters within a period of time

The following data can be displayed on the operator’s automated workstation screen:

- Pressure in pipeline or in the wellhead (for borehole pump)

- Water consumption

- Water levels in tanks

- Temperature of the motor winding or bearings (depending on the pump type)

- Speed of pump shaft (frequency converter is required)

- Electric parameters (e.g. voltage, current)

The operator can perform the following actions from his automated workstation:

- Starting / stopping of the pumping units

- Changing of the pumping units performance (frequency converters are required)

- Control of valves and other processing equipment

- Browsing of the equipment data files, logs and reports for any period (day, month, week, year)

Back to the section

Incorrect information block