|

13.08.2012

"Reducing Costs with HMS Pumps", Arab Water World (AWW), August 2012

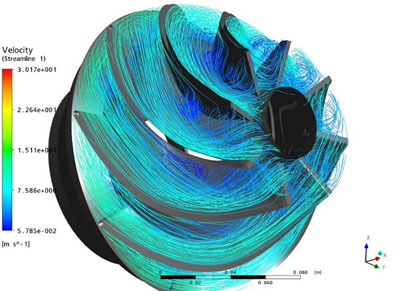

The most obvious criterion for equipment selection is life cycle costs (LCC). Namely all costs are incurred by customer during equipment operation starting from purchase and ending with its disposal. The main costs are the initial cost, energy and maintenance. Engineering solutions intended for their optimization may contradict with each other. Therefore the manufacturer’s task is to reach a compromise among them and find the right balance. Nowadays advanced pumps development seems impossible without modern computer modeling techniques allowing to partially replacing field experiments and getting optimal parameters. HMS Group uses Computational fluid dynamics (CFD) software in pump development including Ciris, a new generation of borehole pumps.

Axial bearing is one of the crucial elements determining motor reliability

Developing Ciris pumps, HMS’s engineers have generated a number of solutions to reduce the impact of negative factors affecting pump operation. The range of electric motors has been designed to have the same diameters. Thus there is no need in cooling jackets; in addition, this allowed reducing additional costs, improving cooling conditions and efficiency. Electric motors have increased length of stator and rotor to enhance reliability and reduce sensitivity to unstable voltage. |

USEFUL LINKS

|

- ProjectsSupporting materials

- | About us

- | Products

- | Services

- | Press-centre

- | Projects

- | Supporting materials

- | Contacts

- | Site map

125252, Moscow, 12 Aviakonstructor Mikoyan street

Phone: +7 (495) 664-81-71, fax: +7 (495) 664-81-72